Understanding SAP Consumption Based Planning – MRP (Part II)

December 20, 2011 1 Comment

Planning Process

The planning process will normally take place at the plant level, but planning at the storage location level can be defined. The following processes are involved in consumption-based planning:

- Firstly, the system will check if a material has been changed relevant to MRP and if it needs to be included in the planning run.

- SAP calculates the net requirements for every material. If the net-requirement quantity is not covered, a procurement proposal is then created.

- Lot-sizing calculation is then performed. Rounding up or down when this is necessary.

- Scheduling is performed to determine the start and finish dates of the planned orders or requisitions.

- Planned orders, purchase requisitions or schedule lines are created by SAP. A supplier can be assigned at this time also.

- Critical situations are identified using exception messages. The planner has to process them manually.

A storage location can be excluded from planning and the stock not be included in the available stocks totals. We can do this at material level in material master (Tr. Code MM02) selecting the appropriate value for the MRP indicator for the storage location in MRP 4. But we can also exclude a storage location via the navigation path: IMG → Material Management → Consumption-Based Planning → Planning → Define Storage Location MRP per plant.

Planning run can be:

- Total planning per plant

- Online: Tr. Code MD01

- Background job: Tr. Code MDBT

- Single-Item, Single-Level planning → Tr. Code MD03)

- Single-Item, Multi-Level → Tr. Code MD02 (take into account BOM)

The system creates procurement proposals which can be: Planned orders, purchase requisitions or schedule lines. A time fence and a planning horizon can be defined. Once a procurement proposal enter in the planning time fence, no automatic changes happen. On the other hand, the planning horizon is the period in which the materials which have undergone any changes are taken into MRP run.

Two methods are available to evaluate the planning results: the MRP List and the Stock/Requirements List.

- MRP List → Tr. Code MD05

This list contains the planning result information for the material and it is the initial working document for the MRP controller to work from. It is a static list and changes are not reflected on the list until the next planning run.

- Stock/Requirements List → Tr. Code MD04

This list shows the current stocks and requirements situation. It is a dynamic list since it is updated each time it is displayed, that is the reason because we can see an order which does not appear in the MRP List.

Lot Sizing Procedure

Lot sizing procedure gives the quantity to be procured or to be produced. This can be defined in the customizing path IMG → Material Management → Consumption-Based Planning → Planning → Lot-Size Calculation → Define Lot-Sizing Procedure. Three groups are available:

- Static lot-sizing procedures

The procurement quantity is calculated based on the specifications mentioned in the material master. The different procedures in this are:- Lot for lot

- Fixed lot size

- Fixed lot size with splitting & overlapping

- Replenishment up to maximum stock level

- Period lot-sizing procedures

- In this, the system groups the requirements in the defined period and creates a lot. The periods can be defined in days, weeks, months, periods of flexible length equal to posting period,… Splitting and overlapping can also be done. The system sets the availability date to the first requirement date within the period, or the availability date can be set either at the beginning or at the end of the period.

- Optimum lot-sizing procedures

- In the previous procedures, the cost are not taken into consideration. Here the requirements are grouped together in a way which will reduce the cost.

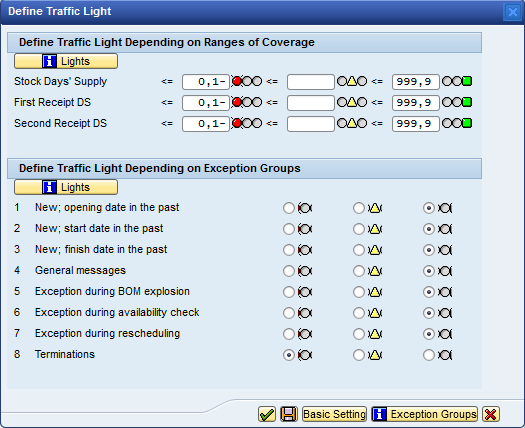

Traffic Lights

Traffic lights indicate the urgency of the materials to be processed. Traffic lights can be defined based on the ranges of coverage and exception groups which can be customized based on the priority. To define the traffic light, go to MD04, then push the overview tree button at top left corner, it will show the traffic lights against the material. We can also see the traffic lights of several material in the MRP List collective access → MD06 (static) and Stock/Requirements List collective access → MD07 (dynamic):

In MD04, right clicking the traffic light will pop up the dialog screen where-in the ranges of coverage and exception group can be defined.

very good